Tips & Trick

On this page we will try to explain the most common defects on Oscar vers 1 coffee machines and procedures to solve problems.

For defect not included in the list please contact us by email describing the exact symptom, preferably accompanied by photos or videos.

The list of symptoms indicated may suggest that coffee machines are not reliable, this is absolutely not true, the Oscar vers 1 is a coffee machine in production since many years and it is very reliable, the list refers to most common defects we may also encounter in other coffee machines of this kind . Over 80% of the defects or symptoms is due to the excessive presence of limestone in the water

For those who are about to carry out the repair themselves it would be very interesting to understand the functioning of the coffee machine with boiler and heat exchanger , in this link the hydraulic diagram simplified.

The central part is the boiler, inside we find the heat exchanger and the heating element.

The boiler is filled with water up to about 2/3 of its capacity , the water is heated by the electrical resistance.

The boiling water is used to generate steam and simultaneously to heat the water within the heat exchanger , the hot water of the heat exchanger will be used for the coffee extraction.

What happens at the initial operation of the coffee machine ?

The boiler is empty of water, the probe of the water level in the boiler detects that there is no water in the boiler , and so the electronic system activate the pump which will suck water from the tank.

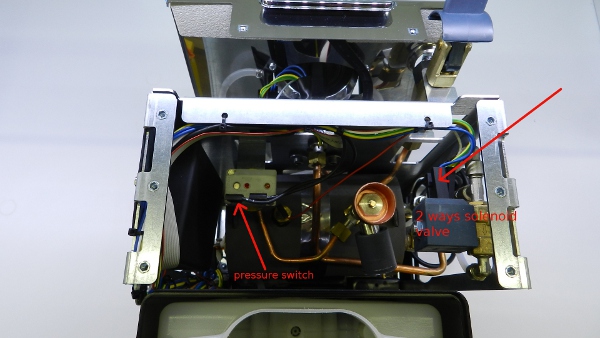

The path of the water will be : Tank, 2-ways solenoid valve, boiler entry ( see photo, GREEN arrow cold water to load water in the boiler).

The boiler will be filled with water until touching the probe of the water level , when water will touch the probe the cycle of pumping water and filling boiler will stop and the heating phase will start (the electric voltage will pass through the pressure switch , the thermal fuse , and finally will feed the electrical resistance).

The heating phase will be about 7-8 minutes, during this time the inside pressure of the boiler will rise up to 1.4 bars, the pressure switch, being set at 1.4 Bars, will interrupt the electric voltage which feeds the electric resistance; obviously if the electrical resistance is no longer fed the internal pressure of the boiler will lower slightly , the pressure switch will perceive this decrease and will be reactivated getting again electrical voltage to the electrical resistance.

The time will be ON for about 20 seconds and the time OFF approximately 180 seconds.

The hot water of the boiler will heat the water in the heat exchanger.

In the machine there is an hydraulic circuit " thermosiphon " , this circuit is required to heat the coffee group.

Since the coffee group is detached from the boiler, the coffee group should be " cold " , the thermosiphonic circuit makes water flow perennially through the coffee group, so that the coffee group is warm even when the machine is in standby.

Path of the hot water to extract the coffee: when you push the button coffee dispenser the pump is activated,the water will flow through the double fitting of the 2-ways solenoid valve and through the retaining valve,the water will push the water present in the heat exchanger, when the button coffee dispenser is activated the 3-ways solenoid valve is activated too and is opened letting hot water flow through the coffee group.

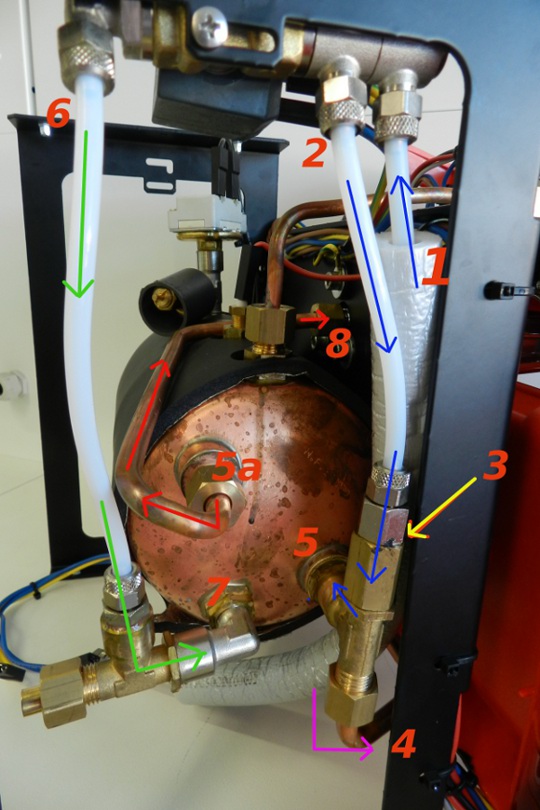

Water circulation, arrow BLUE water COLD, arrow RED HOT water, arrow GREEN COLD water to filling water in the boiler, arrow FUCHSIA HOT and COLD water mixed, direction coffee group

1) cold water which comes from the pump

2) cold water coming out from the fitting double

3) check valve into the fittings, the water can pass in only one direction, downwards

4) water mixed hot water and cold water that goes in the direction of the coffee group for the effect thermosiphonic

5) cold water inlet in the heat exchanger

5A) hot water outlet from the heat exchanger

8) hot water outlet, direction coffee group

6) 2-way solenoid output cold water for boiler filling

7) cold water inlet for filling the boiler

5A) hot water outlet from the heat exchanger

8) hot water outlet, direction coffee group

4) HOT and COLD water mixed, direction coffee group

Pay attention to the electric tension inside coffee machine and always proceed in absence of electric tension

The advice has been prepared for informational purposes only, we do not guarantee the accuracy and integrity of the information and assume no responsibility for any problems or damages arising

It is highly recommended the use of a good coffee grinder

The basic rules:

To get a good hot coffee and a lot of steam, coffee machine should be switched on at least 25-30 minutes before use. Following a list of steps:

1) Always place the cups on the top of the machine, a good barman will always have warm cups.

2) Leave the filter holder placed into the coffee group (without coffee).

3) Turn on the machine, leaving opened the valve knob (clockwise). This is not necessary if you have the antivacum valve.

4) Once a little water comes out from the steam tube, close the steam valve.

5) When the machine has reached the warming temperature and the light is swiched off, open the steam valve again and let some steam go out, the light is switched on again to indicate that the heating element is under electric tension. At this time you push the button to make coffee to allow hot water pass through the filter holder and warm it up.

6) Immediately after using steam to heat milk open valve steam again, in this way lance steam will be cleaned from remaining milk.

7) When coffee is made release the filter holder to avoid to damage the group gasket.

8) use always water with no limestone, all inside pieces includes boiler are made in copper, and limestone can obturate coffee machine.

9) clean the machine periodically as described in the manual

PROBLEMS YOU CAN FIND WITH OSCAR, INDEX:

1) Led "no water in the tank" is switched on although water tank is full

2) The coffee is not hot (see also main rules)

3) Water comes out from the steam nozzle

4) The coffee is cold (the pump works well, the heating element light is always turned on)

5) The coffee is cold (the pump works well, the heating element is always switched off)

6) Steam is coming from the safety valve

7) The water that comes out of the coffee group is insufficient or has little pressure

8) A lot of steam comes out from the coffee group

9) Steam is not coming out from the steam wand

10) Too much water in water tank drain

11) Replacing the group gasket

12) The residual-current device (called also RCD, RCCB, safety switch) of the home electric circuit intervenes when we turn on Oscar

13) Procedure UNOFFICIAL recommended for descaling heat exchanger

1

Led "no water in the tank" is switched on although water tank is full

Probably an air bubble has formed on the hydraulic circuit.

Proceed in one of the ways described below:

1) Lift up and reinsert quickly the water tank for 3-4 times

or

2) Leave button coffee distribution pressed, press and release the general switch several times and quickly for at least 4-5 times.

2

The coffee is not hot (see also main rules)

The boiler temperature is too low.

Probable Cause: The probe of the water level has gone out off setting (this depends on the natural distortion of teflon due to temperature and long running) and the boiler is filled with too much water.

Procedure:

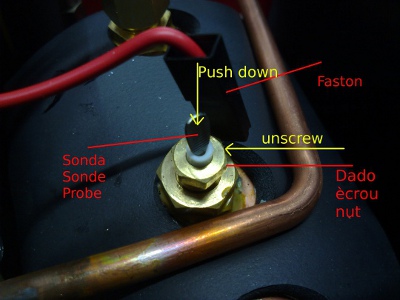

The first thing you must do is to unscrew the nut, then push down the probe.

Always use two wrenches, one wrench tightens a nut and the other one unscrew the nut

Lock the nut shown by yellow arrow, loosen the nut shown by red arrow

After the probe has been pushed down, screw the nut.

Next empty the water boiler. To do this, switch on OSCAR, leaving the steam valve opened. When the water begins to go out from the steam nozzle turn off OSCAR immediately, disconnect power, remove the water tank and slant OSCAR. At this point a lot of water and steam come out from steam pipe. Leave OSCAR inclined till water and steam come out any longer.

Now put OSCAR in the normal position, wipe OSCAR well, insert the tank full of water and switch on the coffee machine again.

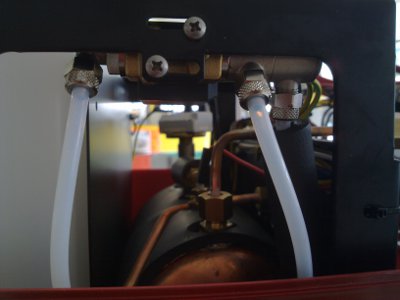

Another cause could overfill the boiler: the 2-ways solenoid valve, code 04100005, does not close properly, a few drops of water can slide through the solenoid 2-ways, drop after drop the boiler will fill excessively. To verify that the 2-ways solenoid valve works well detach the tube shown in the photo below

The test to be done with cold machine ! Press the brew button, if the solenoid valve works well no drop SHOULD COME OUT from the fitting of solenoid

Another cause for coffee not enough hot is the obstruction of the heat exchanger, read paragraph at the end of page for the operations of decalcification

3

Water comes out from the steam nozzle

Probable Cause: 2 ways solenoid filled with limestone or, rarely, solenoid broken.

Before replacing the 2-ways valve, follow the procedure as described in section "the coffee is not hot"

4

The coffee is cold (the pump works well, the heating element light is always turned on)

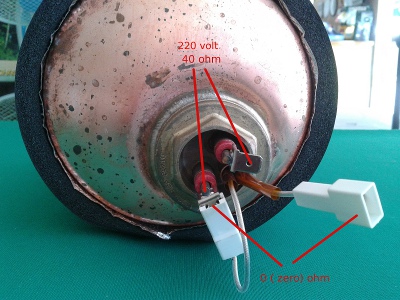

Probable cause: the heating element (code 14100040) is defective, the thermal protector (code 09500014) is defective

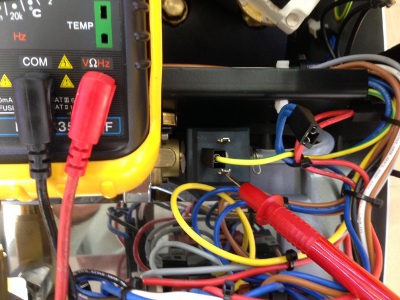

With a multimeter, Vac range, make these measurements: Place the probes of the multimeter on the heads of the resistance, you should read 220 volts AC, the voltage is present

If we read 220 Vac we have to switch off coffee machine, disconnect the heater element plugs and thermal protector plugs , place the probes of the multimeter (OHM range) to the heads of heating element, we should read about 40 ohms, place the probes of the multimeter to the heads of the thermo protector we should read 0 (zero ohms). Finally we can replace the defective element.

5

The coffee is cold (the pump works well, the heating element is always switched off)

Probable cause: the pressure switch, code 09200014 is defective, disconnect the plugs of the pressure switch and with a multimeter (range OHM) measure the value in ohms, if the reading is infinite ohms the pressure switch is defective, if the value is 0 (zero) ohms the pressure switch is not defective

If after doing all measurements the elements tested are not defective it is advisable to make a short circuit of short duration of the two wires connected to pressure switch, sometimes (even if the pressure switch measured by the multimeter seems to be not defective) the pressure switch under voltage may give false measurements.

If we short-circuit the two wires and the voltage does not arrive to the heating element the defect could have two origins:

The electronic unit is defective , code 04900195, (unfortunately there is no way of testing it but replacing it) or that the electronic unit can go into protection.

What are the reasons why the electronic unit goes into protection?

The first cause (the most obvious) there is no water in the tank, but we realize it easily, water tank empty light is ON

The second cause is a little more complex: when we switch on OSCAR the machine checks if there is enough water in the boiler and the electronic unit makes the pump run for a while, if there is an obstruction the pump will emit a deaf noise, the circulation of water will stop and the water tank empty light will be switched ON, as a consequence the electronic unit will not deliver the voltage to the heating element

We could describe this defect with another symptom:

The light of the heating element switches on for a moment and then immediately switches off.

We hear the pump running for a while, shortly after the indicator light of lack of water in the tank flashes

How can we check if water circulation is regular ?

All tests must be made by machine with cold boiler.

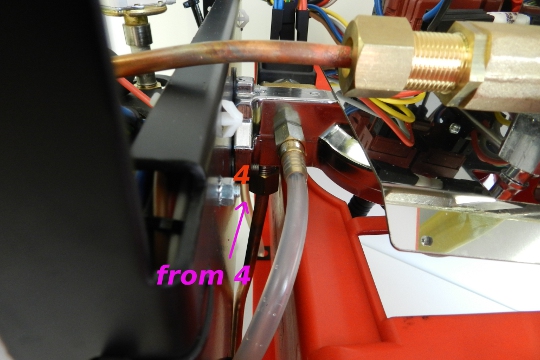

First we see if the pump pushes water, we unscrew fitting, as shown below, of the 2 ways solenoid valve, then we push coffee dispensing button, if the pump works well the water will come out from the teflon tube.

we have to screw the teflon tube that we had disconnected and we disconnect the wire of the probe of the water level as shown below

we turn on Oscar, we will feel immediately that the pump starts and that water will be released from the fitting shown in the picture below

if the water comes from the fitting the solenoid valve is functioning

In this case you should look for the fault obstruction fittings as in the picture below

.

Below there are two videos to show how easily access within the Oscar and the replacement of the heating element

6

Steam is coming from the safety valve

The main causes which make steam come out from the safety valve are two:

Pressure switch, code 09200014, or safety valve, code 98013020, are defective, more likely the pressure switch is defective

The replacement of the pressure switch or the safety valve is very simple, see video

7

The water that comes out of the coffee group is insufficient or has little pressure (it is assumed that the filter coffee is clean, the shower of the coffee unit is clean)

The 3 ways solenoid valve, code 04100038, is probably clogged.

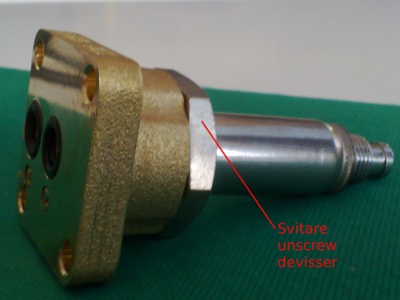

- Remove the transparent tube, unscrew the nut 3-ways solenoid valve,

- Remove the coil and unscrew the two screws

- Switch on OSCAR and press the coffee dispensing button, water will immediately come out from the inferior hole of the coffee group, see picture below

If water comes out from the hole shown in the picture the pump works well, the heat exchanger and pipes are free.

- Then unscrew the cylinder of 2 ways solenoid valve and clean thoroughly, be very careful that the hole shown in the picture below is completely cleaned

8

A lot of steam comes out from the coffee group:

If the coffee machine is switched ON for a long time it is normal that steam comes out instead of water.

From the moment we push the coffee button steam may come out for 4-5 seconds

There are two copper pipes carrying hot water to the group, in these two pipes there is always water. The two pipes are connected to the boiler, the boiler heats the water that remains in the pipes transforming the water into steam. When the pump is functioning the water will push steam at the exit of the coffee

IT IS NOT NORMAL THAT STEAM ALWAYS COMES OUT, which is the cause?

Probably retaining valve CO10, code 01000090, is broken. In this case the hydraulic circuit is discharged and a lot of steam will be produced

The small pieces of plastic of CO10 could go into the hydraulic circuit, in some cases this may clog the 3 ways solenoid valve, we could have little water coming out from the coffee group or it could happen that water does not come out at all. Follow the above procedure to check the functioning

9

Steam is not coming out from the steam wand (the heating element light goes off normally, then the temperature of the boiler is correct)

The probable cause is to be found in the steam tap and more precisely in the valve, this valve, identified by the color green, "is glued, is sticked"

Unscrew the nut of the copper pipe from the boiler, press lightly on the green valve, screw the nut

follows video

Video to see how to unscrew the steam valve to make the replacement of O'ring seal, code 02280011 + 0280004, the piston, code 07300358, the pin of the tap, code 98008004

Another cause for which steam is not coming out from the steam wand is wear of brass steam tap pin, cod. 07300358 or steam tap piston, cod. 98008004

10

Too much water in water tank drain.

The neplex valve, code 98120001, is defective.

TOP - INDEX

11

Replacing the group gasket (at this purpose we made the video using material we normally have at home)

12

The residual-current device (called also RCD, RCCB, safety switch) of the home electric circuit intervenes when we turn on Oscar

Evidently there is an electrical component of Oscar defective, hypothesis 1; or if the residual-current device jump after the Oscar has reached temperature, hypothesis 2, there is a water leak that wets an electrical component. The electrical defective component has a loss to ground, sometimes the loss is a few ohms, and sometimes the loss is of thousands of ohms

In Oscar there are few electrical components: 2-ways solenoid valve, 3-ways solenoid valve, heating element, pressure switch, electronic card.

We have to use a multimeter, we select OHM for maximum range of the instrument, The LCD of the digital multimeters will not display any value if the resistance is infinite, see image

NOTE: in the absence of a multimeter we can establish the faulty component as well. Disconnect the component one at a time (resistance, 2-way solenoid valve, 3-way solenoid valve, pressurestat (always with the two component plugs disconnected), engage the plug and see if the differential jumps if not move to the next component until you find the one defective

Or it will show a resistance X, in the image below we simulated a short circuit, the ohmic resistance we read is 000

We must verify that between one end of the components mentioned above and ground (frame of Oscar, Oscar boiler or better yet central plug of the power plug) there is no ohmic resistance, the measured resistance must be infinite

It is important to disconnect the two plugs powering the electrical components that you want to measure otherwise the measurements will be incorrect and distorted

We start from the solenoid 2-ways, code 04100005

disconnect the two plugs

we measure the electrical resistance, as described and verify the ohmic resistance read.

We still remember that the resistance reading must be infinite, if on the other hand we read a few thousand ohm, or less, the 2-ways solenoid valve is defective.

Same operation has to be done on other electrical components mentioned above, until we will not find the one that has a loss to ground

PRESSURESTAT code 09200014

PRESSURESTAT

3 WAYS SOLENOID VALVE

3 WAYS SOLENOID VALVE code 04100038

3 WAYS SOLENOID VALVE

HEATING ELEMENT code 14100040

HEATING ELEMENT

Sometimes it can happen that due to a water leak the water itself goes on the electronic board making jump the residual-current device, in most cases it is sufficient to dry the electronic board with a hairdryer thus avoiding the replacement of the electronic board

13

To descale, I will quote a text written by the engineer of the Nuova Simonelli

Procedure UNOFFICIAL recommended by Nuova Simonelli for descaling the Nuova Simonelli Oscar or Musica

If you use a Brita filter properly or water with a low content of limestone, the amount of limestone deposited in the machine will be very low.

Therefore descaling every six months will certainly be enough.

Use citric acid is quite appropriate. Oscar or Musica is a coffee machine with heat exchanger, the part to be descaled is the circuit of the heat exchanger.

The central boiler is only used to generate steam and this process actually uses a very small amount of water.

The descaling of the boiler is not necessary at all.

To descale the heat exchanger, follow this procedure:

Dissolve 150-200 grams of citric acid in hot water and pour it into the tank until filling tank completely.

Operate the pump to let half liter of water and citric acid pass through the heat exchanger.

Wait 5 to 10 minutes and repeat with another half liter.

Again wait 5 to 10 minutes.

Fill the tank with fresh water and rinse the system with two liters of water. Finish by passing a final water adding a teaspoon of baking soda to neutralize any traces of acid that may still be present.

Our remarks :-)

The procedure explained by the engineer is correct but provided that:

1) The procedure is done at least every 6 months and low water lime content is used. The risk, if the machine is too calcified is that the water inlet of the heat exchanger becomes clogged irreparably.

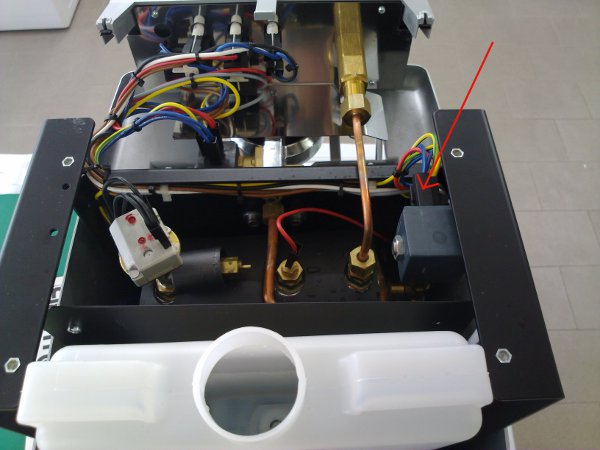

2) Before starting the procedure, it is ESSENTIAL to disconnect one wire of the 2-ways solenoid valve

We explain the reason why these two points are important: If you do the procedure after too long time and the machine is too full of lime, water inlet to the heat exchanger can be found clogged with pieces of tartar, that could obstruct the acid flow . If you see the hydraulic diagram of the NS Oscar, it is easy to understand that if the water inlet of the heat exchanger is clogged, then the water solution of citric acid passes trough the 3 way solenoid valve immediately to the coffee group, the water doesn't circulate in the heat exchanger.

Before starting the procedure is ESSENTIAL to disconnect the connections of the 2-way solenoid, you have to disconnect one wire ( blue or red it does not matter ).

Oscar vers. 1

Musica

Oscar vers. II